Stiefelmayer Metrology: Ensuring High Precision from Design to Series Production

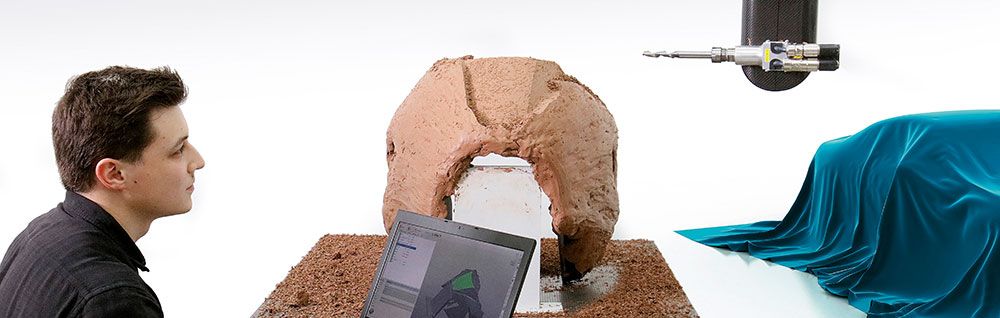

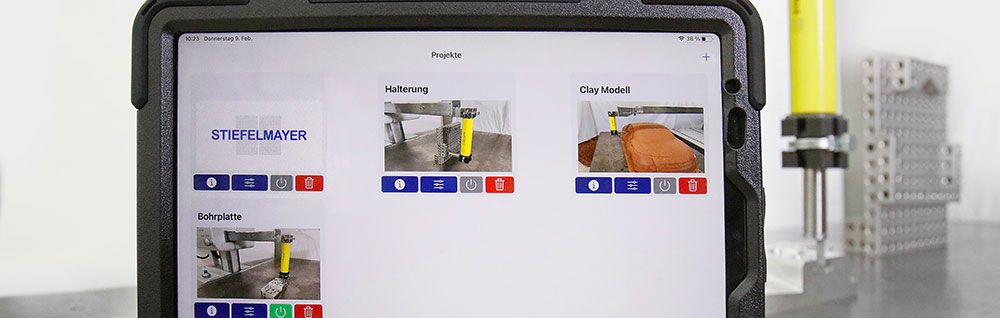

Stiefelmayer-Messtechnik is a leading producer of horizontal arm measuring machines. Our systems are designed for layout tasks, manual measuring as well as complex CNC measuring procedures.

We see ourselves as providers for tailor-made solutions. We therefore offer a large range of machine systems and equipment options. This includes well-designed software systems, field-proven equipment and sensor technology as well as an experienced and reliable service.

The first 3D coordinate horizontal arm CMM was introduced by Stiefelmayer already in the early 70s. Today, more than 8000 measuring and layout machines are installed worldwide: In design studios, prototype construction, pre-series production or for the measuring of large individual components.

Here are some typical applications for STIEFELMAYER horizontal arm machines:

- Measuring of components - doors, hatches etc. - on meisterbocks

- Inspection of parts in interior and exterior cubing

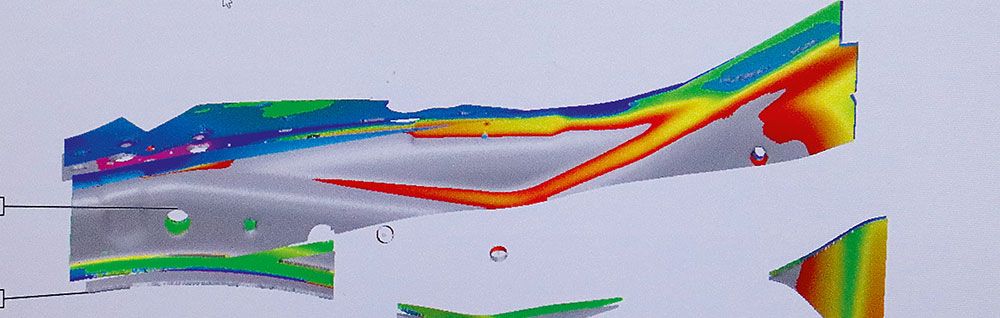

- Analysis measurement of series parts

- Prototypes: Qualifying of components, Marking-out of sections and bores

- Measuring of serial parts made of sheet metal, plastics and carbon

- Layout tasks on bulky castings

Menu

Menu